Looking for high-quality and customizable retail displays?

Look no further than Store Display (SD)!

You can count on us for every detail

All-around support through every process detail

Full-time support and feedback for project production are always on standby from our technologically advanced production workshop, from income raw material testing, production, and distribution to final after-sales follow-up, accompany customers in the whole process of various Customized projects including Packaging, POP&POS display, intelligent display, etc., closely cooperate and execute with the production team in each link.

Capabilities

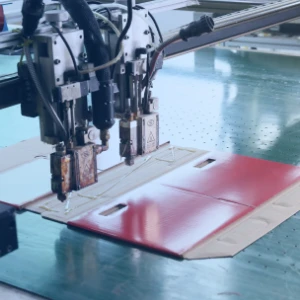

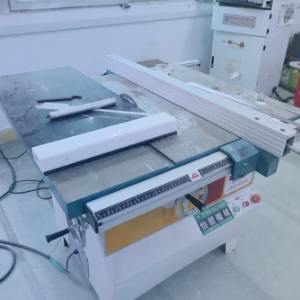

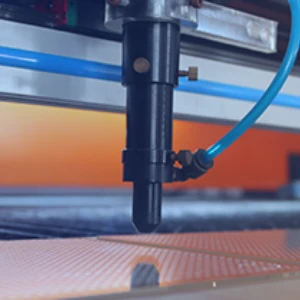

Over the years, our workshop equipment and process flow have been continuously optimized and grown in a more environmentally friendly and more automated direction to ensure that our production solutions keep up with the ever-growing and changing customer needs. Utilizing the most advanced production lines to ensure production efficiency and originality, and maintaining high industry standards in terms of craftsmanship and quality to provide customers with a full range of project efficiency.

Manufacturing

- 300,000 sqft Independent Industrial Park

- 10+ Mega Production Machine

- 100+ of Manufacturing Expert

- Complete & Organized Production Line

Manufacturing

We follow a uniform inspection after each process step is completed, and the completion of each step and process must pass the inspection before it can be sent to the next workshop or production line, which includes incoming material inspection, structural verification, load-bearing test, Anti-collision test, packaging test, etc.

SD’s unique secondary QA control process, that is, each process and production process has passed the inspection during the production line circulation process, and our quality inspection team will follow the comprehensive quality inspection process before the final shipment by full or random inspection again. the finished bulk goods can be transferred to the logistics and delivery department until the second test is all qualified.

- Burn-In Test

- Daylight Appearance Matching Test

- Functionalities Checking

Intelligent Display Function QC Process

- Transportation Test

- Dropping Test (1 Angle, 3 Line, and 6 Surface)

- Weighting Test

- Color Matching

- Sampling Matching

Traditional Display QC Process

- Smoothness Test Park

- Fracture Strength Test

- Temperature Resistance Test

- Crease& Stiffness Test

Package QC Testing